Color steel plate common standard and present situation

What is the common standard, the common standard before 2004 color coated plate should be the national standard, that is, the substrate galvanized double-sided greater than 180g/m2, the surface coating greater than 20um, back paint coating greater than 10um, higher than the national standard for the non-common standard.

Since 2007, as a result of the increase in the number of manufacturers, the vicious market competition intensified, some enterprises have to lower the coating and coating to lower the price, and one after another to the local quality inspection bureau for the record far lower than the national standard of enterprise standards. As a result, the double-sided galvanized layer from 180g/

㎡to 120g/

㎡,60g/

㎡,40g/

㎡,the current double-sided common zinc layer has been reduced to 12g/

㎡,the plate rust has no real effect; Color coated layer paint from 20μmdown to12μm,9μm,back paint from 10μmdown to7μm、5μm、3μm, color steel service life has been greatly shortened.

Especially because of the vicious competition in the coating market, manufacturers will be high weather resistant resin materials to the poor weather resistance of the phthalic anhydride and alkyd synthesis, and even some enterprises will be organic pigment to the very cheap dye pigment, resulting in color steel fast fade and powder. As a result of the majority of users to color steel raw materials lack of professional, only from the surface is difficult to distinguish, in order to avoid causing heavy losses, prudent selection is the best choice.

Special quality of Magnesium Aluminum Zinc coated steel plate of Nantong Glory

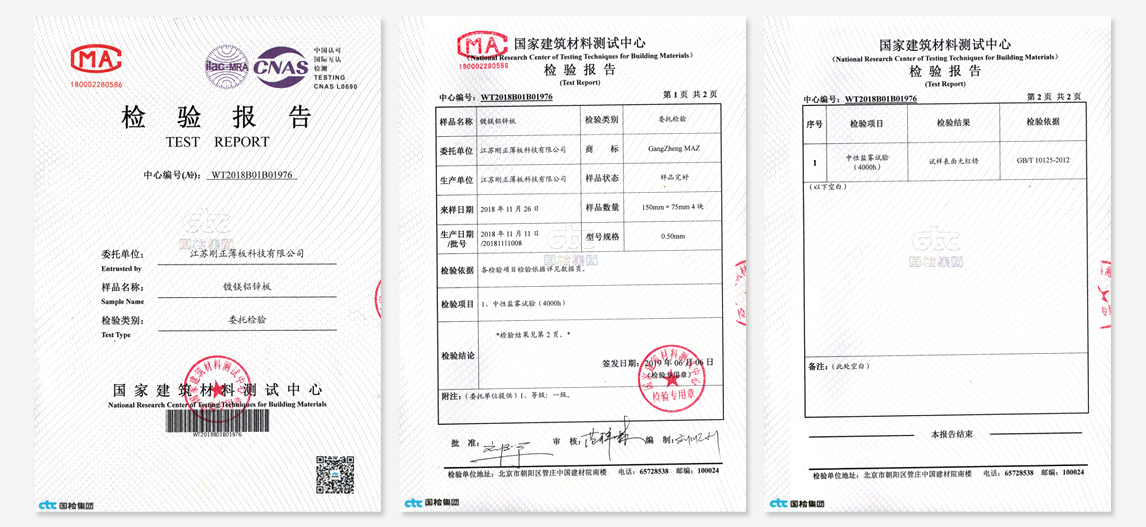

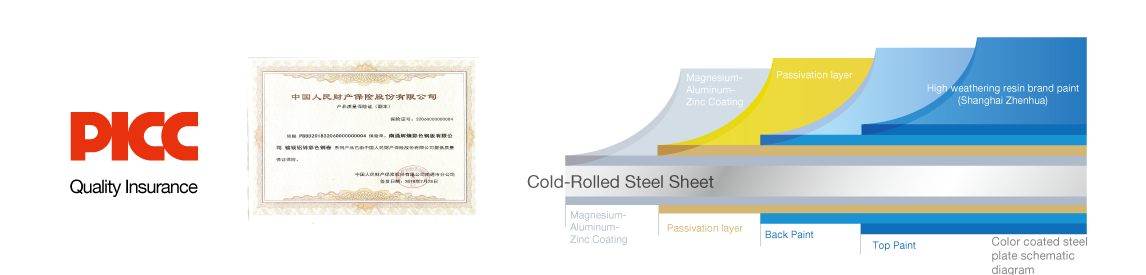

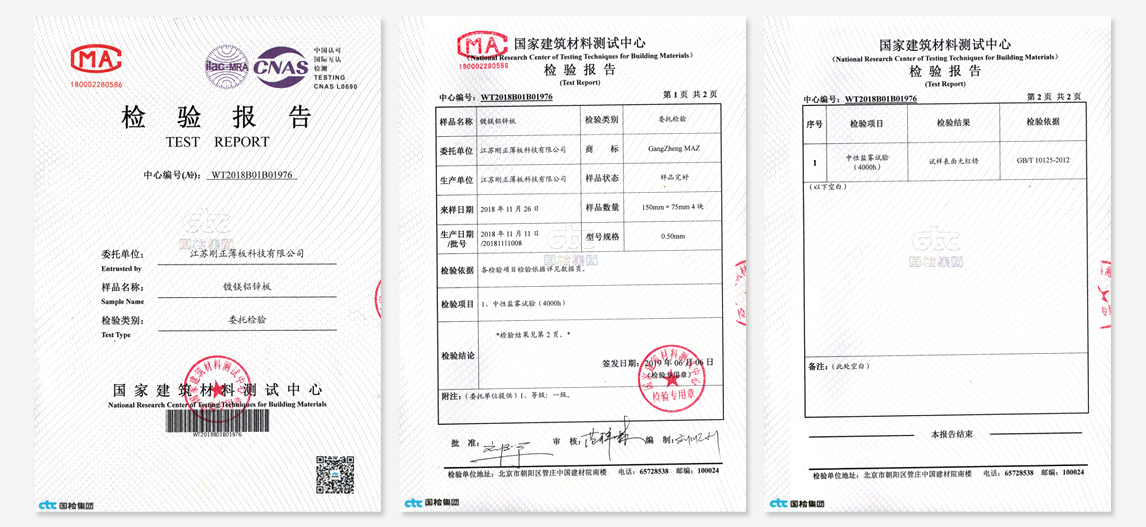

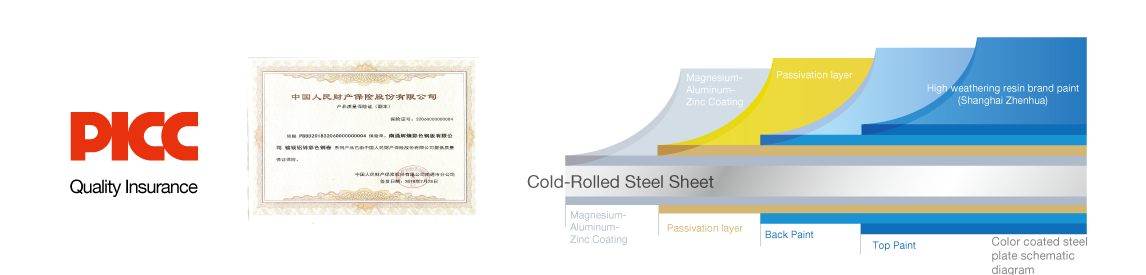

Magnesium Aluminum Zinc coated steel plate is produced by Nantong Glory Color Steel Plate Co., Ltd which are assured products insured by PICC.

Nantong Glory Color Steel Plate Co., Ltd from March 2009 since the comprehensive use of high weathering resin coating, abandoned the general coating factory products, long-term and baosteel designated supply Shanghai zhenhua, Akzo Nobel and other first-class coating enterprises to ensure the weatherability of the product, away from fading and powder, as new day.

In order to firmly safeguard the interests of customers and resist the defective products, we has formulated strict standards for the coating and coating of various specifications of products as well as the raw and auxiliary materials to effectively protect the interests of customers.

To further improve the service life of the product, 2017 our company after hundreds of times test, data acquisition, analysis, nearly one thousand times finally developed with strong corrosion resistance of Magnesium Aluminum Zinc products, the product color steel substrate, the brilliant color steel quality and the improvement of the larger, just real magnesium aluminum plated zinc caigang is really take the customer as the center, creating customer value products.

Technology of Gangzheng Steel Magnesium Aluminum Zinc products

Technology of Gangzheng Steel Magnesium Aluminum Zinc products

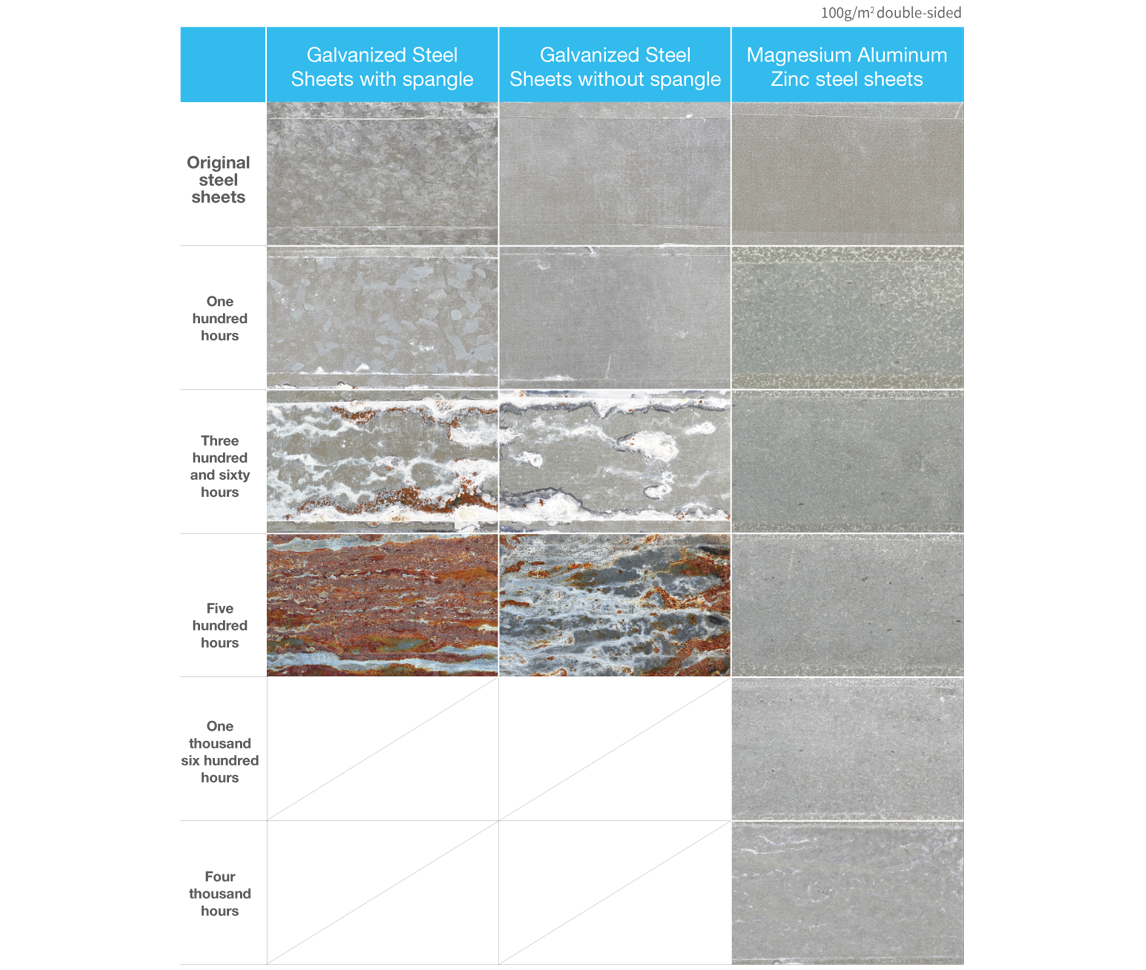

Gangzheng brand Magnesium Aluminum Zinc products have super corrosion resistance and scratch resistance. Our company conducted salt spray test on 100 grams of magnesium, aluminum and zinc plating and 100 grams of zinc plating on a year-on-year basis. It was found that when the galvanized board reached 360 hours, the board surface had red rust, while the galvanized board had not seen red rust for more than 4000 hours. It can be seen that the corrosion resistance of magnesium, aluminum and zinc plating plate is more than 10 times of galvanized plate, greatly enhance the service life of the product, reduce the user's use cost.

Magnesium Aluminum Zinc products have the cutting end face and welding end corrosion mechanism, when cutting end face and welding end sill bare, for cutting around the end of the end face and welding special plating the composition of the melt out of form hydrogen zinc oxide(Zn(OH)²), alkaline zinc chloride(ZnCL2.4Zn(0H)²)and(Mg(0H)²) ingredients such as the density of formation protection film, in a certain period of time these ingredients will cover the cutting face, the protect skin membrane conductivity is extremely low, has played a very good inhibitory effect of corrosion.

Our company has won the national invention patent for the high corrosion resistance magnesium aluminum zinc plating products. We choose to use the genuine magnesium aluminum zinc plating as the color coating substrate, which can further improve the product quality and better create practical value for customers.

Main properties of Gangzheng Magnesium Aluminum Zinc steel sheet and Zinc steel sheet SST test (Salt-Spray Test)

Main properties of Gangzheng Magnesium Aluminum Zinc steel sheet and Zinc steel sheet SST test (Salt-Spray Test)